Industrial Cameras For Pharmaceutical Inspection

Ensuring Pharma Safety, Quality, And Traceability

Inspect tablets, vials, syringes, labels, and serialization with industrial cameras. Ensure dose accuracy, traceability, and defect-free production for safe pharmaceutical delivery.

Technical Requirements

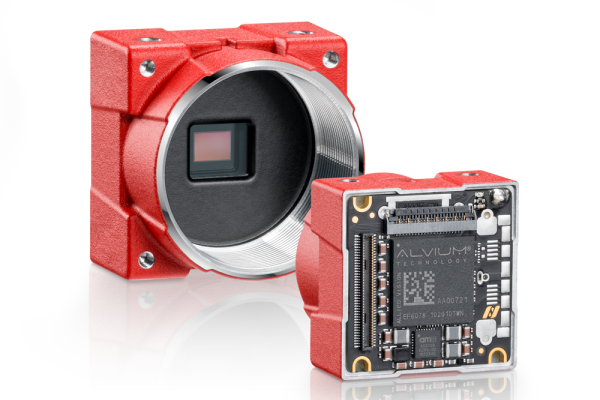

- Robust IP65/IP67 rated high-resolution cameras for reliable inspection in pharmaceutical environments

- High color fidelity for inspection of packaging, tablets and diagnostic applications

- Fast image acquisition and high image transfer rates enabling fast pharmaceutical production throughput

- Advanced trigger options and synchronized lighting for precise synchronization of processes

- SWIR technology to look through opaque packages or blister material

Do You Have Any Questions? We Are Here To Help.